Menu

close

CHP system’s crankshaft is connected to a synchronous alternator; such alternator can generate 20kWel (peak value). Heat recovery system can release till 40kWth of heat power (peak value), using the heat of engine cooling system and the heat released by exhaust engine gases.

CHP system is suitable even for trigenerative purposes (production of electric energy, heating, and refrigerator), if coupled with an absorption chiller.

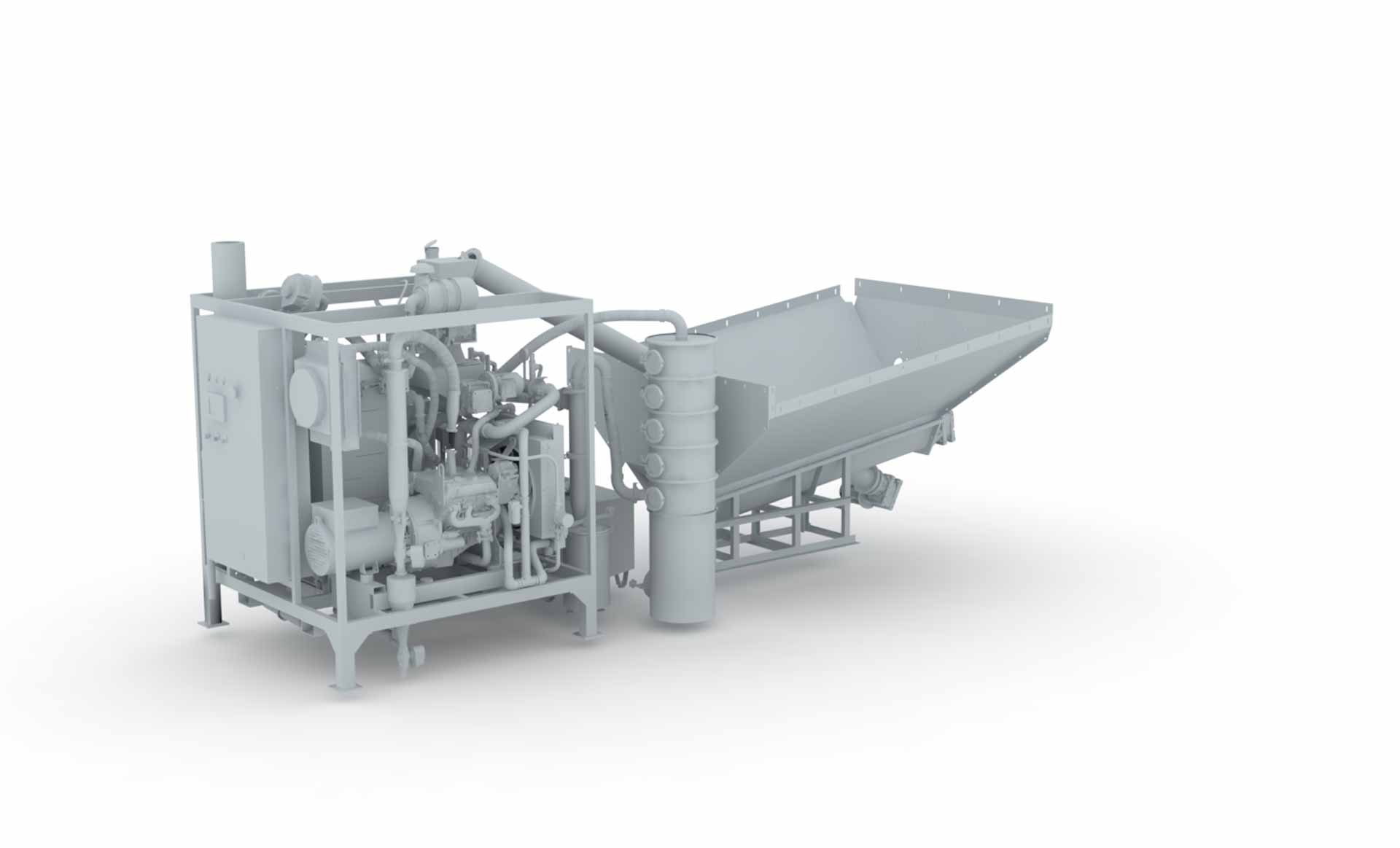

ECO20x working principles for electric energy production are shown in figure.

The electric motor engages the hopper’s auger, pushing biomass inside the reactor.

Thermochemical reactions into the gasifier (pyrogasification) produce a syngas mix to be cooled and cleaned before the use in internal combustion engine.

For this reason, gas is threated by:

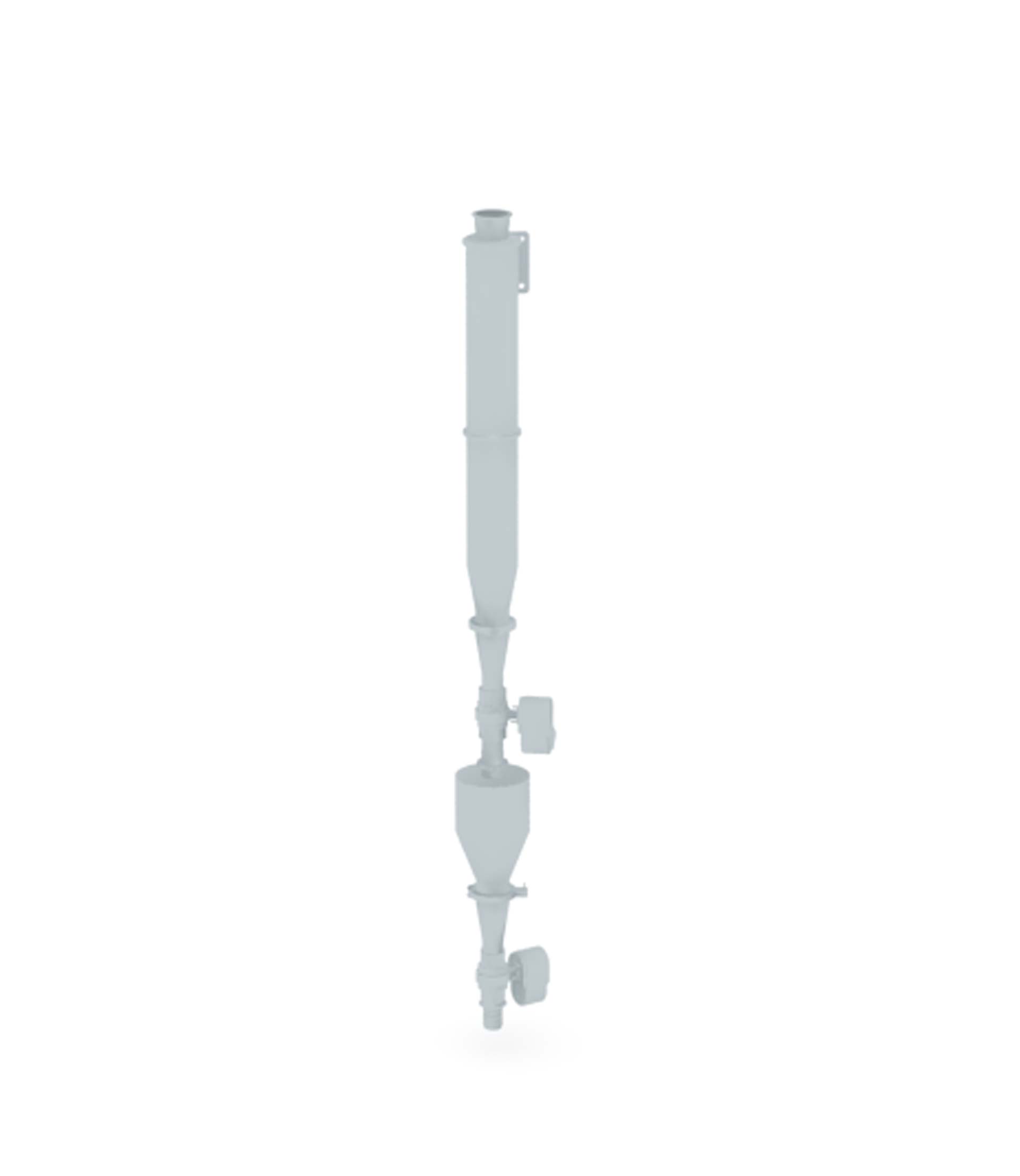

a cyclone (on the reactor) for ultra small ashes removal

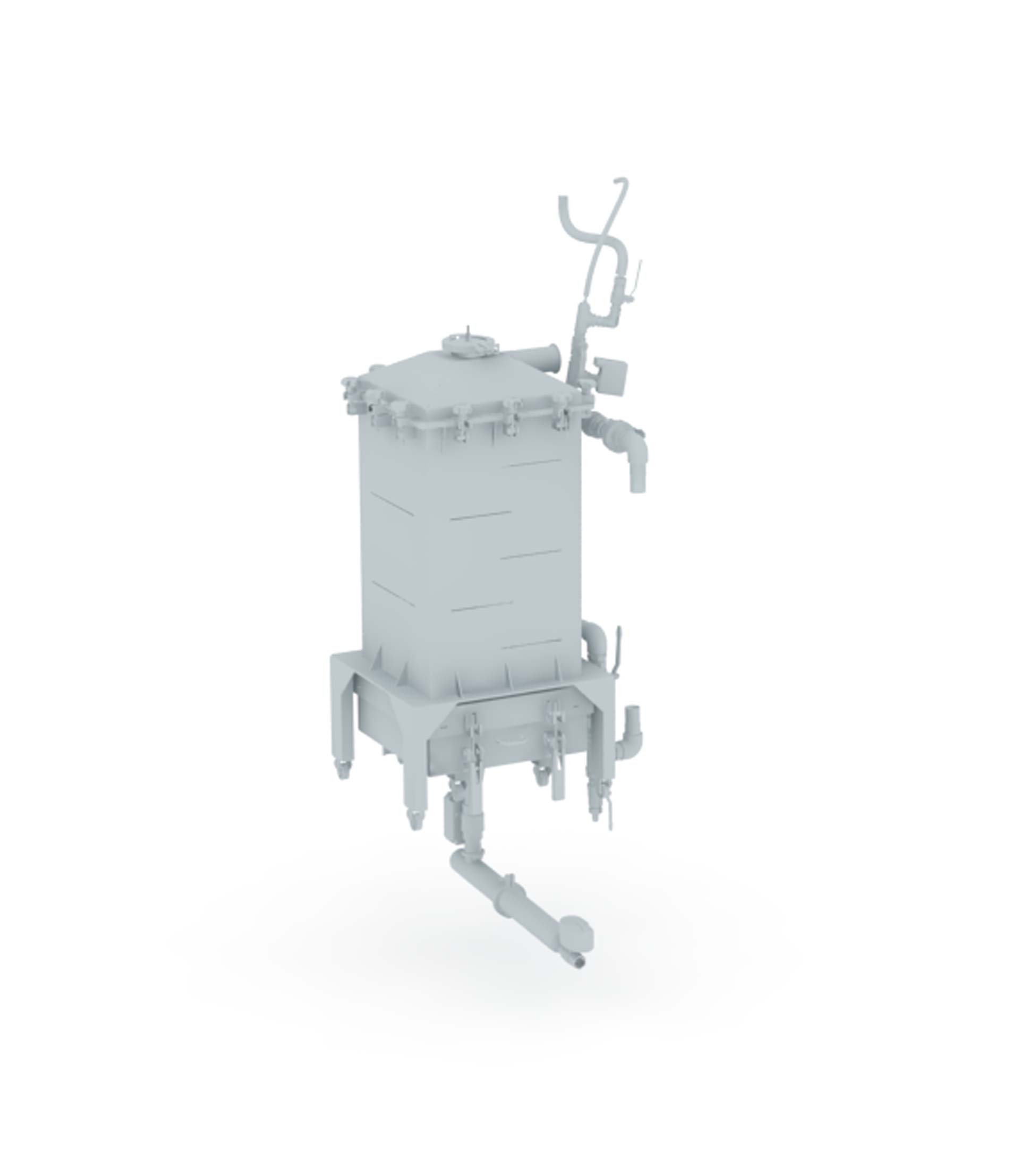

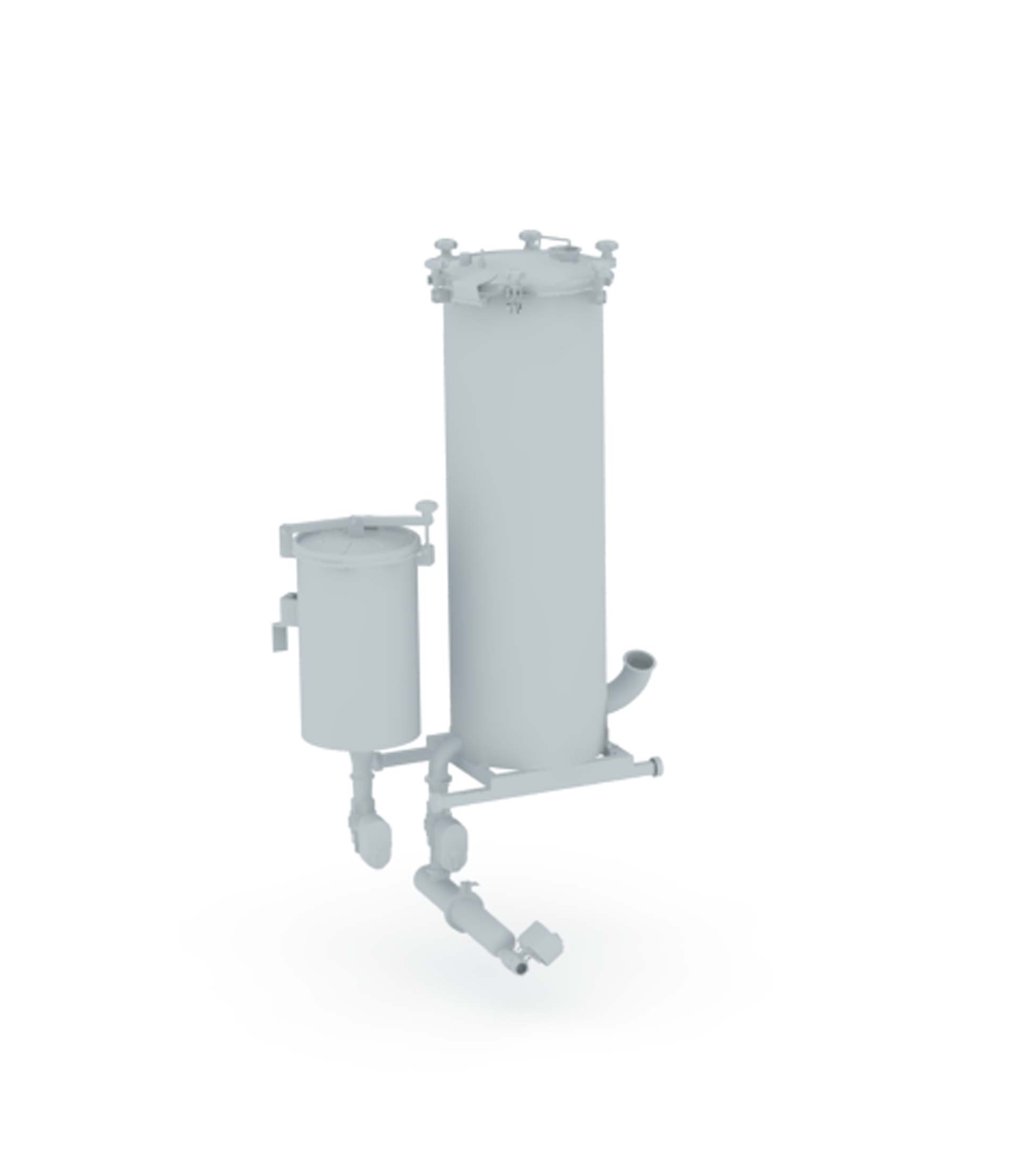

a syngas cooler to reduce gas temperature so to increase the gas density and to condensate steam and tars from syngas stream

a biological filter to further ultra small ashes and residual tars removal

a cyclone upon the engine, allowing the mixture with external air so to obtain the last condensation and related removal.

Concerning thermal recovery section, ECO20x can get:

After heat releasing into the heat exchanger, CHP system's exhaust gas are released in the environment, ever in compliance with current regulations constraints on emissions given by ltalian Legislative Decree 152/06.