Menu

close

ECOBurner is a boiler for civil use, industrial application, agricultural processes and local heating grid.

It is especially deemed for thermal medium-power devices natural gas fed.

CIVIL AND COMMUNITY USE

(local heating grid, hotels, condominiums and buildings)

AGRICULTURAL AND BREEDING SECTORS

(greenhouses and drying devices)

INDUSTRIAL SECTOR

(heating of plants and buildings, drying devices used at sawmills, production processes for which heated water or heated temperature are required)

L’ECO-burner è una caldaia a gassificazione per uso civile, industriale, agricolo e di tele-riscaldamento.

È particolarmente adatto per impianti termici di media potenza alimentati dal gas naturale.

CIVILE

(teleriscaldamento, alberghi, edifici in genere)

AGRICOLO E DI ALLEVAMENTO

(serre o essiccazione)

INDUSTRIALE

(riscaldamento capannoni, edifici, essiccatoi per segherie, processi industriali che necessitano di acqua calda o riscaldamento)

CIVILE

(teleriscaldamento, alberghi, edifici in genere)

AGRICOLO E DI ALLEVAMENTO

(serre o essiccazione)

INDUSTRIALE

(riscaldamento capannoni, edifici, essiccatoi per segherie, processi industriali che necessitano di acqua calda o riscaldamento)

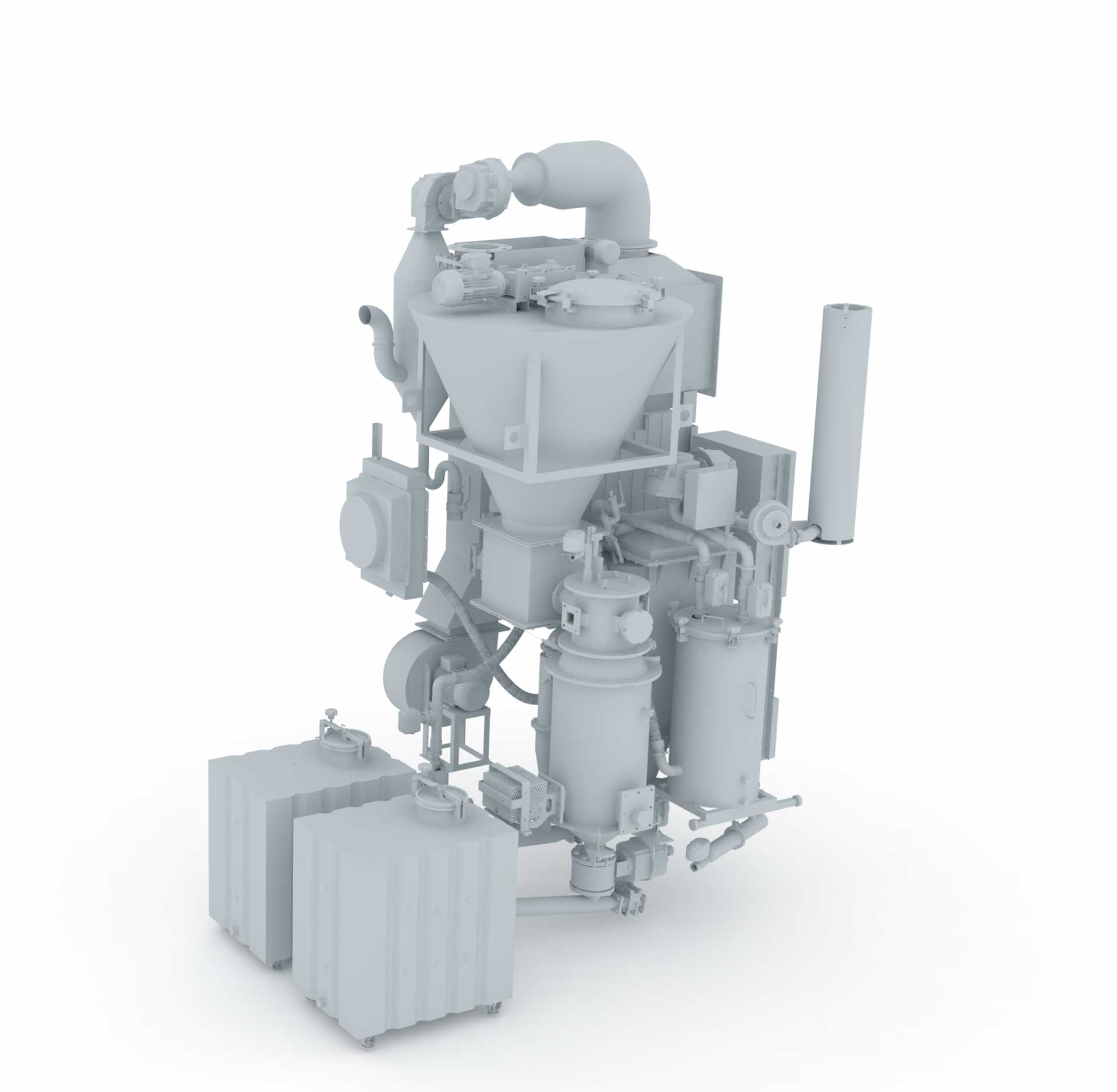

ECOburner uses the gasification process: a kind of gas "extraction" from wooden-based biomass.

Like conventional boiler, in the same way ECOburner heat can be generated by gas 'extracted' from wooden waste combustion, but not methane or LPG, burns.

The fuel tank is positioned on the equipment rear, from it the biomass is continuously released to the reactor converting it into a burnable gas mixture.

The reactor, or gas producer, is composed by a thick layer of refractory insulating material, around a steel core reactor where, high temperatures (1000°C) are reached and the gasification process takes place.

After gas production, the combustion takes place in another compartment of the boiler: the burner. Here the gas mixture ignites completely, reaching the heat exchanger surface, releasing its thermal power for air or water heating until to be released through exhaust chimney.

The ECOburner is managed by an electronic control system, through the touch panel on board the customer can set the working condictions, regulating the temperature process, the primary, secondary and exhaust gases circulation or locking, and other parameters.

ECOburner can generate more than 100 kW of thermal power.

It is suitable for heating solution in small buildings, agricultural companies and other applications.

Cluster installation available: multiple installation for more thermal power (200 kWp, 300kWp…).

ECOBurner can be powered by a wide range of materials, in compliance to the following simple constraints.

This system is characterized by:

Lo sfruttamento del gas generato è massimo, evitando così la formazione di piccole particelle di residui incombusti presenti nelle caldaie tradizionali.

ECO-Burner allows immediately to replace traditional boilers conventional fuels fed (diesel, LPG, methane, mains gas) with this innovative system maintaining the same thermal power, however, just using vegetable waste.

It allows a costs decreasing of the raw materials, in addition to advantages for the environment due to its use.

ECOBurner can be also used in combination with burners conventional gas/diesel fuels fed.

Easy maintenance: this activity is a little bit more than the ashes and condensation removal.

The ECOBurner is a latest generation gasification boiler and it is in compliance with the required EU regarding thermal power production and environmental respect to be eligible for tax refundings or breaks.